In the world of construction and manufacturing, creating strong, durable, and flexible bonds between materials is essential. One of the most versatile and widely used solutions for this purpose is joint adhesive. Whether you’re sealing expansion joints in concrete, bonding tiles, or waterproofing roofs, joint adhesive plays a critical role in ensuring long-lasting performance. But what exactly is joint adhesive, and why is it so important? In this article, we’ll explore the types, uses, and benefits of joint adhesive in construction, with insights from CUALI, a trusted brand in building chemical solutions.

What is Joint Adhesive?

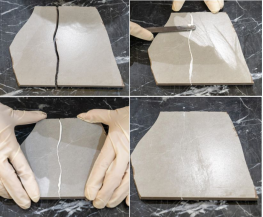

Joint adhesive is a specialized bonding material designed to fill, seal, or strengthen gaps (joints) between two surfaces. These adhesives are formulated to withstand environmental stressors like temperature changes, moisture, and mechanical movement, ensuring a durable and flexible bond. Joint adhesives are commonly used in construction, manufacturing, and DIY projects to prevent cracks, leaks, and material degradation.

Types of Joint Adhesive

There are several types of joint adhesives, each tailored to specific applications and performance requirements. Here are the most common types:

1. Epoxy Joint Adhesive

Epoxy-based joint adhesives combine resin and hardener to create a rigid, chemical-resistant bond. They are ideal for heavy-duty applications where strength and durability are critical.

•Features: High strength, chemical resistance, minimal shrinkage.

•Uses: Concrete joints, metal-to-metal bonding, structural repairs.

2. Polyurethane Joint Adhesive

Polyurethane adhesives are flexible and weatherproof, making them suitable for outdoor or dynamic environments.

•Features: Elasticity, UV resistance, waterproofing.

•Uses: Expansion joints, roofing, automotive panel bonding.

3. Silicone Joint Adhesive

Silicone adhesives excel in high-temperature and waterproofing applications.

Features: Heat resistance, flexibility, water repellency.

Uses: Bathroom joints, glass bonding, HVAC systems.

4. MS Polymer Joint Adhesive

MS (Modified Silane) polymer adhesives offer a balance of flexibility and strength without solvents.

Features: Low VOC, adhesion to multiple substrates, durability.

Uses: Flooring joints, window installations, exterior panel bonding.

5. Acrylic Joint Adhesive

Fast-curing and cost-effective, acrylic adhesives are used for lightweight bonding.

Features: Quick setting, paintability, moderate strength.

Uses: Drywall joints, decorative trim, DIY projects.

Uses of Joint Adhesive in Construction

Joint adhesive is a versatile material with a wide range of applications in construction. Here are some of the most common uses:

1. Sealing Expansion Joints in Concrete

Expansion joints in concrete floors, bridges, and pavements require flexible joint adhesives to accommodate thermal expansion and prevent cracking. Polyurethane and MS polymer adhesives are ideal for this purpose.

2. Bonding Tiles and Flooring

Joint adhesives ensure a strong bond between tiles, wood, or other flooring materials, preventing movement and gaps. Epoxy and acrylic adhesives are commonly used for flooring applications.

3. Waterproofing Roofs and Walls

Polyurethane and silicone joint adhesives are excellent for sealing roofs, walls, and other exterior surfaces, providing a waterproof barrier against rain and moisture.

4. Securing Panels and Trim

In construction and manufacturing, joint adhesives are used to bond panels, trim, and decorative elements. MS polymer adhesives are particularly effective for this purpose.

5. Repairing Cracks and Gaps

Joint adhesives can be used to repair cracks in concrete, drywall, or other materials, restoring structural integrity and preventing further damage.

Benefits of Joint Adhesive in Construction

Joint adhesive offers numerous benefits that make it indispensable in construction projects. Here are some of the key advantages:

1. Durability

Joint adhesives create strong, long-lasting bonds that withstand heavy loads, vibrations, and environmental stressors.

2. Flexibility

Many joint adhesives, such as polyurethane and MS polymer, remain flexible after curing, accommodating movement and preventing cracks.

3. Weather Resistance

Joint adhesives are designed to resist moisture, UV rays, and temperature fluctuations, making them ideal for outdoor applications.

4. Chemical Resistance

Epoxy and silicone joint adhesives resist chemicals, oils, and solvents, ensuring performance in industrial or harsh environments.

5. Ease of Application

Joint adhesives are easy to apply using caulking guns, trowels, or other tools, making them suitable for both professionals and DIY enthusiasts.

6. Aesthetic Finish

Some joint adhesives, such as silicone and MS polymer, cure to a smooth, paintable finish, enhancing the appearance of the bonded surface.

How to Choose the Right Joint Adhesive

Selecting the right joint adhesive depends on the specific requirements of your project. Here are some factors to consider:

1.Substrate Material: Choose an adhesive compatible with the materials you’re bonding (e.g., concrete, metal, glass).

2.Environmental Conditions: Consider temperature, moisture, and UV exposure.

3.Flexibility Needs: For dynamic joints, opt for flexible adhesives like polyurethane or MS polymer.

4.Curing Time: Some adhesives cure quickly, while others allow more time for adjustments.

5.Strength Requirements: For heavy-duty applications, epoxy or polyurethane adhesives are ideal.

CUALI’s Joint Adhesive Solutions

CUALI offers a range of high-performance joint adhesives tailored to diverse construction needs:

•Epoxy Joint Adhesive: For heavy-duty, chemical-resistant bonds.

•MS Polymer Adhesive: Flexible, eco-friendly option for flooring and exteriors.

Pair with CUALI’s complementary products, such as epoxy grout or solid surface adhesive, for a complete bonding solution.

Conclusion

Joint adhesive is a versatile, essential material for sealing and bonding gaps in construction, manufacturing, and DIY projects. From sealing expansion joints in concrete to waterproofing roofs, joint adhesives ensure durability, flexibility, and weather resistance. By understanding the types, uses, and benefits of joint adhesive, you can select the right product for your project and achieve long-lasting results.

For reliable, high-performance joint adhesives, trust CUALI’s expertise and premium product range. Explore our solutions today and experience the CUALI difference in quality and performance!