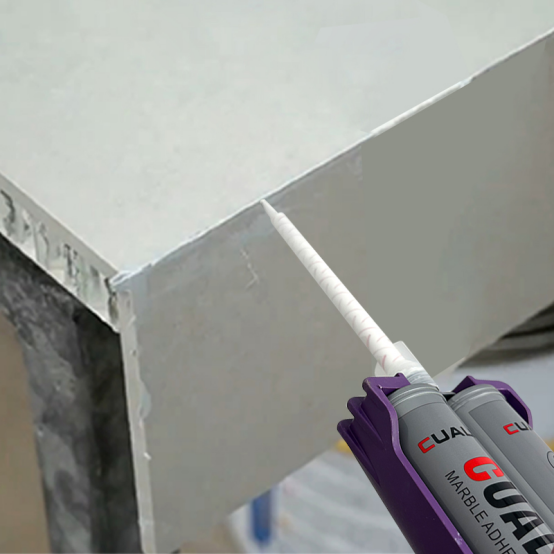

When it comes to bonding solid surfaces like countertops, sinks, and wall panels, the choice of adhesive is critical. CUALI, a trusted brand in building chemical solutions, offers a premium epoxy adhesive that doubles as a high-performance solid surface adhesive. This versatile product is engineered to deliver seamless, durable, and invisible bonds, making it ideal for both commercial and residential applications. In this article, we explore how CUALI’s epoxy adhesive can be used as a solid surface adhesive, its benefits, applications, and best practices for flawless installations.

What is Solid Surface Adhesive?

Solid surface adhesive is a two-part (or sometimes one-part) adhesive system engineered to bond solid surface materials. Unlike standard construction adhesives, it is optimized to:

•Match Material Properties: Mimic the thermal expansion, hardness, and flexibility of solid surfaces.

•Create Invisible Seams: Cure to a clear or color-matched finish, ensuring joints blend seamlessly with the surface.

•Withstand Demanding Conditions: Resist moisture, heat, and chemicals common in kitchens, labs, and healthcare settings.

Key Features of Solid Surface Adhesive

1.Seamless Bonding:

Forms invisible joints, critical for countertops and vanity tops where aesthetics matter.

2.High Strength:

Provides structural integrity, preventing separation under load or temperature changes.

3.Chemical and Heat Resistance:

Withstands exposure to cleaning agents, hot pans, and moisture without degrading.

4.Sanding/Finishing Compatibility:

Once cured, the adhesive can be sanded, polished, and shaped to match the solid surface.

5.Fast or Controlled Curing:

Some formulas cure quickly for efficiency, while others allow time for precise alignment.

Applications of Solid Surface Adhesive

•Countertop Seaming: Joining slabs to create long, continuous surfaces (e.g., kitchen islands).

•Edge Banding: Attaching edge profiles to countertops.

•Repairs: Fixing chips, cracks, or delamination in existing solid surfaces.

•Fabrication: Bonding sinks, backsplashes, or decorative inlays to solid surface panels.

Commercial Installations: Healthcare counters, lab benches, and hotel vanities.

What is Epoxy Adhesive?

Epoxy adhesive is a two-part bonding agent composed of resin and hardener. When mixed, these components create a strong, durable, and chemically resistant bond. CUALI’s epoxy adhesive is specially formulated to meet the demands of modern construction and fabrication, offering exceptional strength and versatility.

Why Use Epoxy Adhesive as a Solid Surface Adhesive?

Solid surface materials like Corian®, Hi-Macs®, and other acrylic/polyester composites require adhesives that can:

•Create invisible, seamless joints.

•Withstand moisture, heat, and chemicals.

•Match the material’s thermal expansion and flexibility.

CUALI’s epoxy adhesive meets these requirements, making it an excellent choice for solid surface bonding. Here’s why:

1. Seamless Bonding

Epoxy adhesive cures to a clear or color-matched finish, ensuring joints blend seamlessly with the solid surface. This is critical for countertops, vanity tops, and other applications where aesthetics matter.

2. Exceptional Strength

With high tensile and shear strength, epoxy adhesive prevents separation under load or temperature changes, ensuring long-lasting durability.

3. Chemical and Heat Resistance

CUALI’s epoxy adhesive resists exposure to cleaning agents, hot pans, and moisture, making it ideal for kitchens, labs, and healthcare settings.

4. Sanding and Finishing Compatibility

Once cured, epoxy adhesive can be sanded, polished, and shaped to match the solid surface, ensuring a flawless finish.

5. Versatility

Beyond solid surfaces, epoxy adhesive can bond metals, ceramics, and wood, making it a valuable tool for various construction and fabrication projects.

Applications of Epoxy Adhesive in Solid Surface Bonding

1. Countertop Seaming

Epoxy adhesive is perfect for joining solid surface slabs to create long, continuous countertops or kitchen islands. Its seamless bonding ensures a smooth, invisible joint.

2. Edge Banding

Attach edge profiles to countertops with epoxy adhesive for a clean, professional look.

3. Repairs

Fix chips, cracks, or delamination in existing solid surfaces using epoxy adhesive. Its strong bond restores the surface’s integrity and appearance.

4. Fabrication

Bond sinks, backsplashes, or decorative inlays to solid surface panels with ease.

5. Commercial Installations

Use epoxy adhesive for healthcare counters, lab benches, and hotel vanities, where durability and hygiene are paramount.

Benefits of Using CUALI’s Epoxy Adhesive

1. Durability

CUALI’s epoxy adhesive creates bonds that withstand heavy use, temperature fluctuations, and mechanical stress.

2. Aesthetic Perfection

The adhesive cures to a clear or color-matched finish, ensuring invisible seams that enhance the solid surface’s appearance.

3. Low Maintenance

Epoxy adhesive resists stains, moisture, and chemicals, reducing the need for frequent repairs or cleaning.

4. Eco-Friendly

CUALI’s epoxy adhesive is formulated with low-VOC components, meeting global sustainability standards.

5. Ease of Use

With precise mixing ratios and clear instructions, CUALI’s epoxy adhesive is easy to apply, even for DIY enthusiasts.

Installation Best Practices

To achieve the best results with CUALI’s epoxy adhesive, follow these steps:

1.Surface Preparation:

Clean and lightly sand the bonding areas to remove debris and ensure proper adhesion.

2.Mixing:

Follow CUALI’s instructions to mix the resin and hardener in the correct ratio (e.g., 10:1).

3.Application:

Apply the epoxy adhesive evenly to both surfaces. Use clamps or weights to hold the pieces firmly in place.

4.Curing:

Allow the adhesive to cure for the recommended time (typically 24–72 hours) before sanding or polishing.

5.Finishing:

Sand and polish the cured adhesive to match the solid surface’s texture and gloss.

Why Choose CUALI’s Epoxy Adhesive?

CUALI combines cutting-edge technology with rigorous quality control to produce epoxy adhesive that outperforms competitors. Our product is:

•Tested for Extreme Conditions: Resistant to chemicals, UV rays, and thermal shock.

•Supported by Expertise: Access technical guidance for seamless installation.

•Versatile: Suitable for solid surfaces, metals, ceramics, and more.

Complementary Products for Solid Surface Projects

1. Epoxy Grout

For tiled countertops or backsplashes, pair CUALI’s epoxy adhesive with our premium epoxy grout for a complete, durable solution.

2. MS Polymer Adhesive

For flexible bonding needs, such as outdoor installations, CUALI’s MS polymer adhesive offers superior elasticity and weather resistance.

Conclusion

CUALI’s epoxy adhesive is a game-changer for solid surface bonding, offering seamless, durable, and chemically resistant joints that meet the demands of modern construction and fabrication. Whether you’re installing countertops, repairing surfaces, or fabricating custom designs, CUALI’s epoxy adhesive ensures flawless results.

Upgrade your projects with CUALI’s premium epoxy adhesive—where innovation meets reliability. Visit our website to explore our range of building chemical products today!