Applying epoxy grout sealant using a two-tube cartridge system offers unmatched convenience and precision, but even seasoned DIYers can encounter challenges like bubbles, cracking, or adhesive failure. As a leading manufacturer of high-performance building chemicals, CUALI understands these pain points and has engineered solutions to help you achieve flawless, long-lasting results. In this guide, we’ll break down the root causes of common epoxy grout sealant issues and provide actionable fixes and prevention strategies.

Why Two-Tube Epoxy Grout Sealant?

CUALI’s two-tube epoxy grout sealant is a premixed system where resin and hardener are stored separately in a dual-chamber cartridge. When dispensed through a mixing nozzle, the components combine to form a durable, waterproof seal. Benefits include:

•No Manual Mixing: Eliminates human error in resin-hardener ratios.

•Precision Application: Ideal for tight joints and intricate tile patterns.

•Superior Bonding: Resists cracking, stains, and moisture penetration.

However, improper technique or environmental factors can lead to application issues. Let’s troubleshoot the most common problems.

Issue 1: Bubbles in Epoxy Grout Sealant

Causes

•Trapped Air: Rapid application or uneven pressure on the caulking gun introduces air pockets.

•Improper Priming: Skipping the step to discard the first 5–10ml of epoxy grout sealant leaves unmixed material in the nozzle.

•High Humidity: Moisture reacts with uncured sealant, creating bubbles.

How to Fix Bubbles

1.Puncture and Refill: Use a pin to pop surface bubbles, then inject fresh epoxy grout sealant into the void.

2.Smooth with a Leveling Tool: Press the tool firmly over the affected area to force out air pockets.

3.Wipe and Reapply: Remove bubbled sealant, clean the joint, and reapply CUALI’s epoxy grout sealant slowly.

Prevention Tips

•Prime the Nozzle: Always discard the first 5–10ml to ensure proper mixing.

•Apply Steadily: Use consistent pressure on the caulking gun to avoid air gaps.

•Work in Small Sections: Limit applications to 2x2 ft areas for better control.

Issue 2: Epoxy Grout Sealant Cracking

Causes

•Substrate Movement: Tiles shifting due to temperature changes or unstable surfaces.

•Incomplete Mixing: Resin and hardener not blended thoroughly in the nozzle.

•Rapid Drying: High temperatures or direct sunlight cause the epoxy grout sealant to cure too quickly.

How to Fix Cracks

1.Remove Damaged Grout: Use a grout saw or utility knife to clear cracked sealant.

2.Reapply Fresh Sealant: Inject CUALI’s epoxy grout sealant into the cleaned joint and level smoothly.

3.Control Curing Conditions: Maintain room temperature (15–25°C) during curing.

Prevention Tips

•Stabilize the Substrate: Ensure tiles are firmly adhered to a rigid, dry surface.

•Avoid Extreme Temperatures: Apply epoxy grout sealant in shaded, climate-controlled areas.

•Use Quality Products: CUALI’s epoxy grout sealant is formulated to flex slightly, reducing crack risks.

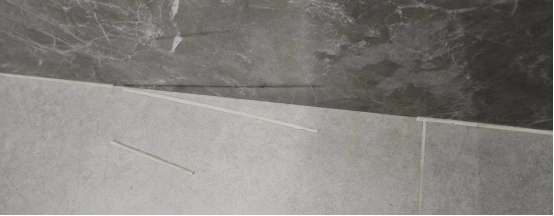

Issue 3: Epoxy Grout Sealant Falling Off

Causes

•Poor Surface Prep: Dust, grease, or moisture on tile joints weakens adhesion.

•Insufficient Sealant Depth: Applying too thin a layer fails to bond with tile edges.

•Expired Product: Old epoxy grout sealant cartridges may have separated components.

How to Fix Fall-Off

1.Clean the Joint: Remove loose sealant and scrub the area with isopropyl alcohol.

2.Reapply Generously: Fill the joint completely with fresh epoxy grout sealant, ensuring full contact with tile edges.

3.Allow Full Cure: Wait 48 hours before exposing to water or stress.

Prevention Tips

•Deep Clean Joints: Use a vacuum or brush to remove debris before application.

•Check Expiry Dates: Only use CUALI’s epoxy grout sealant within its shelf life.

•Apply Adequate Sealant: Ensure the joint is filled to 80–90% capacity.

Issue 4: Uneven Color or Streaking

Causes

•Partial Mixing: Resin and hardener not fully blended in the nozzle.

•Contamination: Dirty tools or surfaces introduce impurities.

•Inconsistent Application Speed: Varying pressure on the caulking gun affects mixing.

How to Fix Color Issues

1.Remove Streaked Sections: Scrape out uneven epoxy grout sealant and reapply.

2.Replace the Nozzle: Clogged or worn nozzles disrupt mixing—swap in a new one.

Prevention Tips

•Prime Thoroughly: Discard the first 10ml of epoxy grout sealant to clear unmixed material.

•Use Clean Tools: Wipe nozzles and leveling tools with acetone before use.

Pro Tips to Avoid Epoxy Grout Sealant Issues

1.Test on a Small Area: Practice applying CUALI’s epoxy grout sealant on spare tiles to refine your technique.

2.Monitor Nozzle Health: Replace mixing nozzles after 2–3 cartridges to ensure proper blending.

3.Follow Curing Times: Respect the 24–48 hour curing window—no shortcuts!

4.Store Cartridges Properly: Keep unopened epoxy grout sealant in a cool, dry place.

Why CUALI’s Two-Tube Epoxy Grout Sealant Minimizes Risks

1.Precision Nozzle Design: Ensures thorough mixing of resin and hardener, reducing bubbles and streaks.

2.Flexible Formula: Resists cracking even under thermal expansion or minor substrate shifts.

3.Enhanced Adhesion: Bonds tightly to tiles when surfaces are properly prepared.

4.UV-Stable Colors: Maintains consistent hues indoors or outdoors.

FAQs About Two-Tube Epoxy Grout Sealant

Q: Can I apply epoxy grout sealant over old grout?

A: No—old grout must be fully removed to ensure proper adhesion of CUALI’s epoxy grout sealant.

Q: How do I clean dried epoxy grout sealant from tiles?

A: Use heat gun to soft the dried epoxy grout, then use a scraper to shave the soft dried epoxy grout, finally clean it with cloth.

Q: Why does my epoxy grout sealant feel tacky after curing?

A: High humidity or low temperatures slow curing—allow extra time or use a dehumidifier.

Conclusion: Master Your Epoxy Grout Sealant Projects with CUALI

Bubbles, cracking, and fall-off are frustrating but avoidable. By understanding the causes and leveraging CUALI’s premium two-tube epoxy grout sealant, you can achieve durable, waterproof, and visually stunning tile joints. Remember: surface prep, proper tools, and patience are key!

Ready to tackle your next project? Explore CUALI’s epoxy grout sealant range today—where innovation meets reliability.